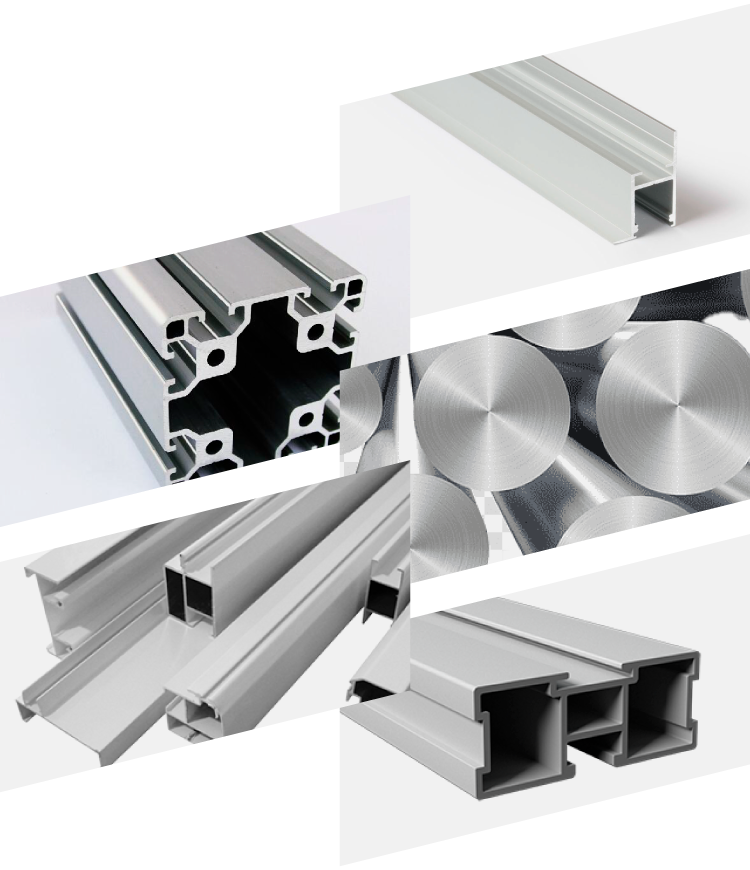

AS PARTNERS, WHAT ADVANTAGES DO WE OFFER?

Mikraltek intends to establish itself as a reference in the development of aluminum profile solutions with high standards of demand and rigor. Designed for profiles with more rigorous dimensional requirements, Mikraltek is a differentiating factor serving the national and international industry.

LOW INITIAL COSTS

The first ones to be pressed before our presses, initial initial costs will be comparatively lower. This fact may allow pre-series or commercial experiments to be carried out prior to mass production. it is equally viable to produce profiles for the work or project carried out.

LOWER COST PER METER

When it becomes possible to reduce the thickness of the profile without the customer's low cost or the quality perceived by the customer, we obtain a higher unit cost per linear meter.

MATRIXES

As a rule, they have fewer restrictions, which leads to narrower dimension variances in the profile and can be narrower and can have more tolerances.

FREEDOM

By working with thinner thicknesses than the market, this allows development equipment to create with fewer creative restrictions. We currently produce profiles with a weight of 66g/ml.

SUSTAINABILITY

Using lighter profiles and the use of raw materials and the respective carbon dependencies associated with both the raw material and the production of the profile.